About Us

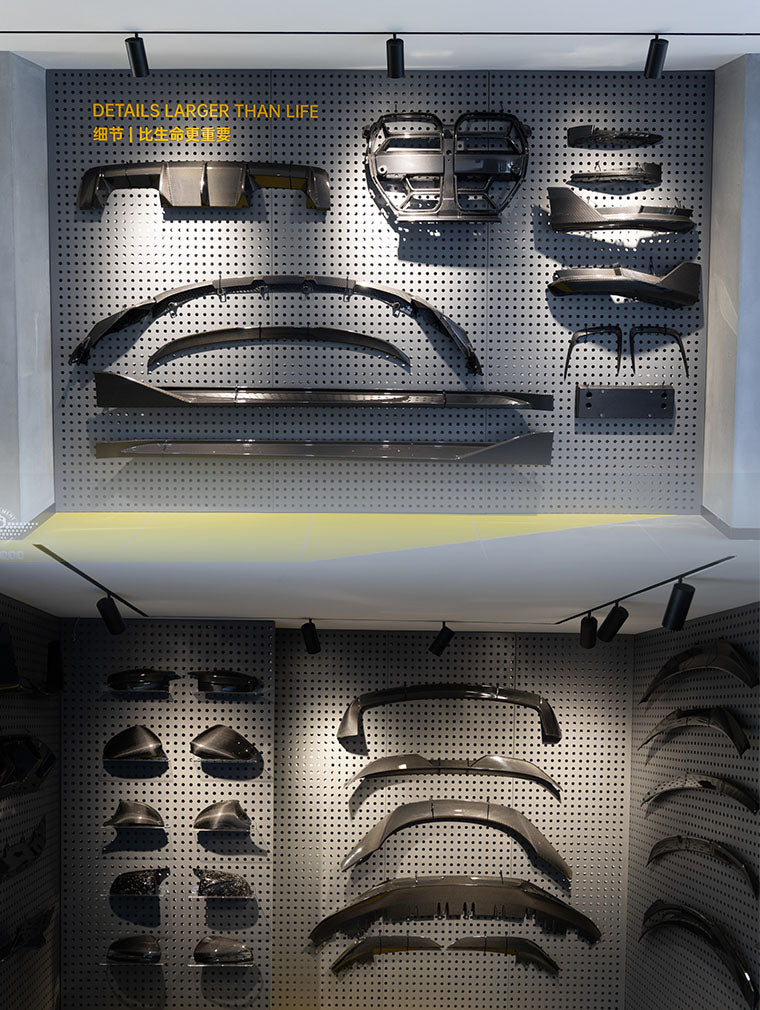

At SOOQOO, we design and manufacture leading carbon fiber automotive parts for a wide range of premium and performance vehicles.

The founders of SOOQOO have been manufacturing carbon fiber parts for over 15 years with world-renowned quality and durability. With the manufacturing expertise already in place, SOOQOO was founded in 2021 so they could bring their vision and designs to life.

Thanks to years of experience and large production volumes, we are able to supply the highest quality carbon fibre whilst offering incredible value for money.

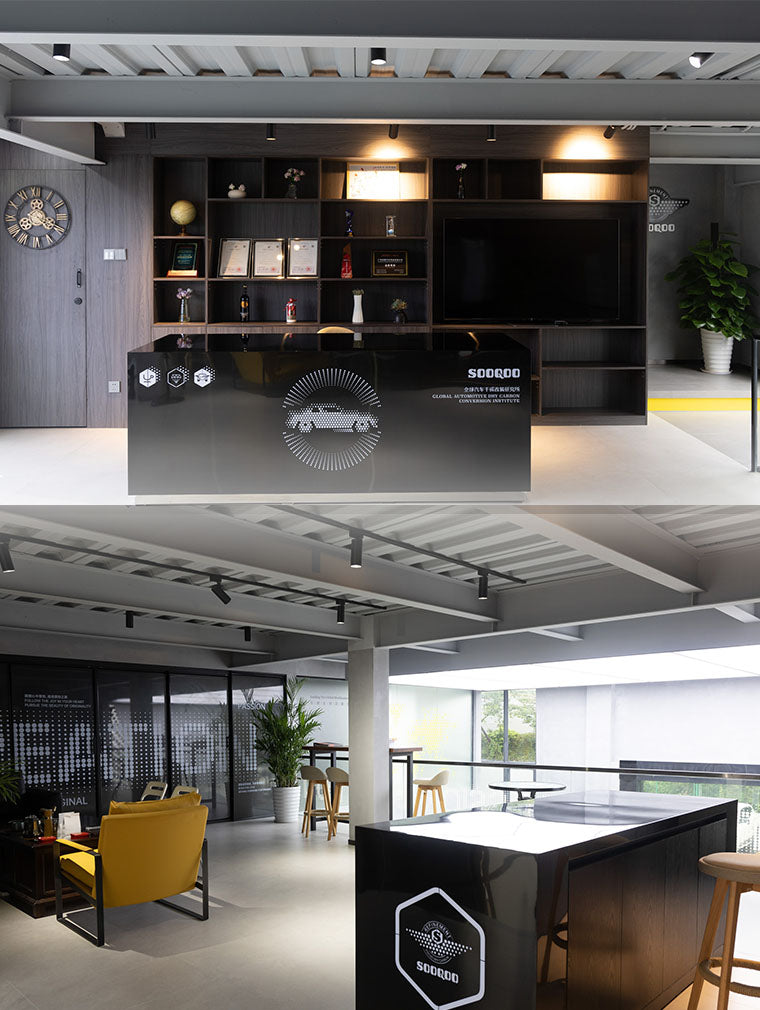

Meet The Team

We are a group of passionate automotive enthusiasts, dedicated to providing the highest carbon quality standards and outstanding customer service. Our office is located in Guangzhou, China, at the heart of the rapid growth in automotive innovation.

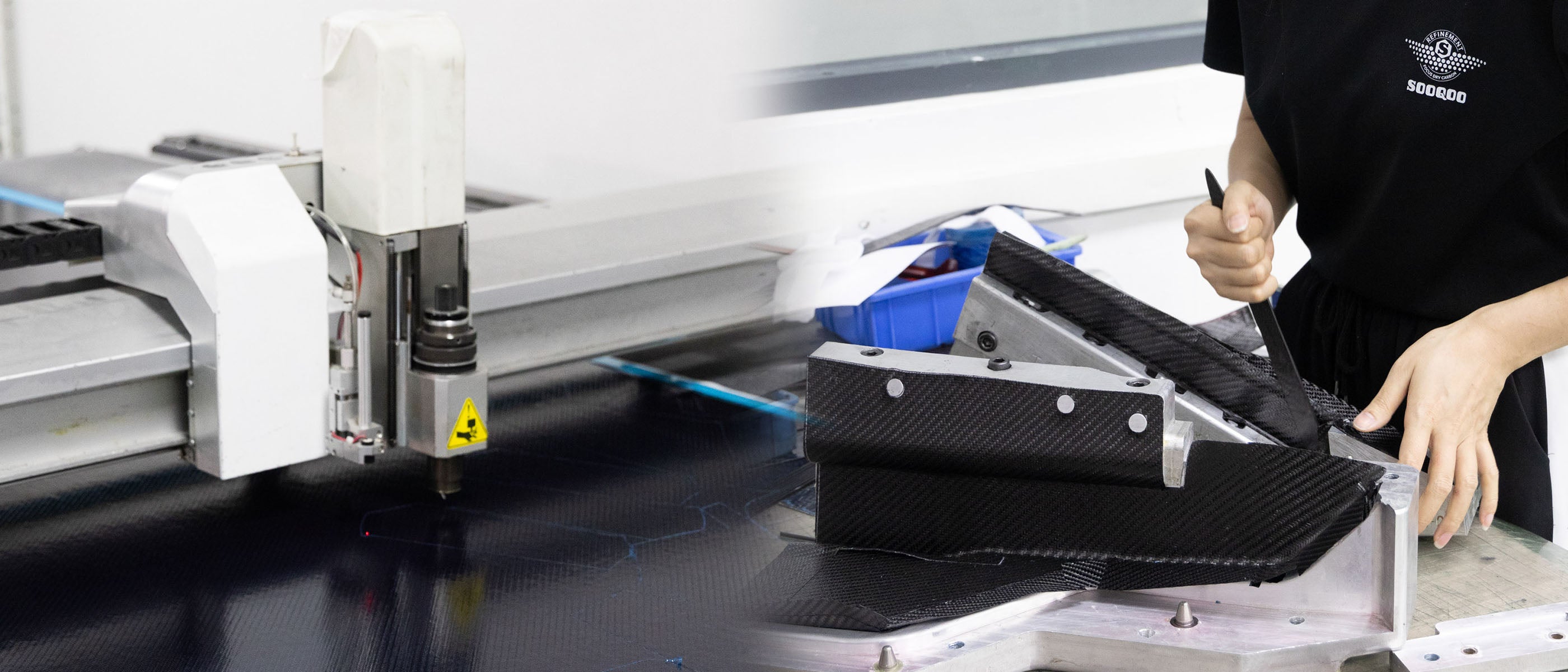

Our Manufacturing Process

Each carbon fibre product that goes through the SOOQOO factory has already been quality-assured through 3D scanning, a meticulous design & testing process, as well as manufacturing techniques backed by 15 years of experience and $15 Million of investment.

Step 1

First, the carbon composite is laser cut to ensure it’s the perfect size for the mould. All moulds are machined from industry-leading aluminium alloy which gives each component perfect fitment every single time.

Step 2

It’s now time for the autoclave process which compresses the parts to prevent any air voids from forming. The part is then tested and additional fixing points are added, if required.

Step 3

The product then undergoes a detailed three-stage quality control process to expose any imperfections or flaws in the product.

Step 4

Upon passing the inspection, the high gloss clear lacquer is applied to provide over 3 years guaranteed UV protection for a long-lasting premium finish.

Our Warehouse

All products are stocked in our warehouse ready to ship worldwide. We have close relationships with a variety of shipping companies including FedEx, UPS and DHL to ensure fast and smooth delivery to you, the customer.